ISBM Machine Injection Stretch Blow Molding Machine

At Ever Power ISBM Machine Co., Ltd, we specialize in high-performance one-step Injection Stretch Blow Molding (ISBM) machines that deliver superior efficiency, precision, and cost savings compared to traditional two-step IBM processes.

One-Step Injection Stretching Blow Molding Machine

The one-step injection stretch blow molding machine provides a highly efficient solution for manufacturing precision plastic containers across various industries. This process integrates the injection, stretching, and blowing stages into a single continuous operation within one unit, eliminating the need for preform reheating or intermediate transport. By completing these steps in one cycle, the ISBM Machine ensures high production efficiency and enhanced product stability, making it ideal for high-precision hollow plastic products.

Utilizing advanced isbm injection stretch blow molding technology, these systems are compatible with a wide range of materials, including PET, PETG, PP, PC, Tritan, PS, ABS, and PLA. This versatility allows for the production of specialized items such as feeding bottles, medical containers, cosmetic packaging, and high-end crafts that require strict dimensional accuracy and optical clarity. Because the entire process occurs in a single stage, the final products maintain superior surface quality and structural integrity without the risk of external contamination or surface abrasions.

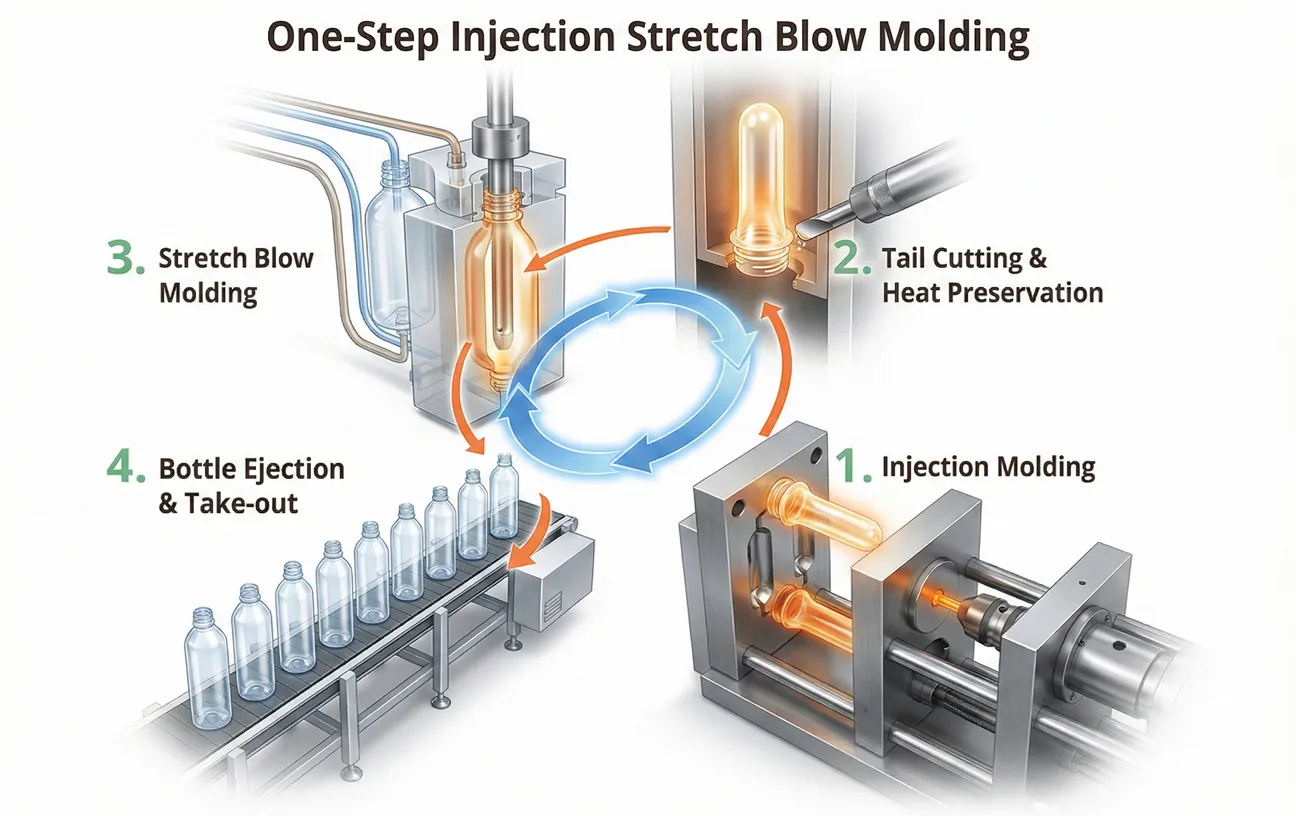

ISBM Process Flow

Our advanced injection stretch blow molding machine integrates four critical manufacturing stages in one seamless operation, delivering superior efficiency and precision from raw material to finished bottle. This single-stage process eliminates the need for separate preform production and reheating, significantly reducing production time and energy consumption.

Injection Molding

High-precision injection of molten plastic resin into the preform mold cavity. The material is heated to optimal temperature and injected under controlled pressure, creating an initial bottle preform with a perfectly formed neck finish. This stage ensures dimensional accuracy and consistent wall thickness distribution, which is critical for the subsequent stretching process.

Tail Cutting & Heat Preservation

Excess material is precisely trimmed from the preform base while maintaining optimal temperature throughout the preform body. This critical stage preserves the ideal temperature profile required for effective molecular orientation during stretching. The heat retention eliminates the need for costly and energy-intensive reheating equipment, resulting in significant energy savings of up to 40%.

Stretch Blow Molding

The heated preform undergoes biaxial orientation through mechanical stretching and pneumatic blowing. A stretch rod extends vertically while high-pressure air inflates the preform radially, conforming it to the final mold cavity shape. This dual-axis stretching process aligns polymer molecules in both directions, dramatically improving mechanical strength, barrier properties, transparency, and impact resistance of the finished bottle.

Bottle Ejection & Take-out

Completed bottles are automatically ejected from the blow mold and transferred to the output conveyor system. The bottles exit the machine at optimal temperature, properly cooled and dimensionally stable, ready for immediate quality inspection, leak testing, and downstream filling operations. This automated extraction ensures consistent handling and minimizes the risk of product damage or contamination.

Core Advantages

Our ISBM Machine technology delivers unmatched efficiency, quality, and cost-effectiveness through innovative single-stage manufacturing. By eliminating traditional two-stage processes, we provide manufacturers with a competitive edge in today's demanding production environments.

Energy Efficient

Our single-stage process eliminates the need for secondary preform reheating, directly maintaining preform temperature from injection through blow molding. This fundamental advantage reduces overall energy consumption by up to 40% compared to conventional two-stage systems.

The one-step injection stretch blow molding machine keeps the temperature of the preform optimized throughout the entire production cycle, eliminating costly infrared heating ovens and their associated power requirements.

Excellent Performance

Biaxial molecular orientation during the stretching process creates bottles with exceptional physical and optical properties. The controlled stretching aligns polymer chains in both longitudinal and radial directions, resulting in significantly enhanced product characteristics.

This advanced stretching technology dramatically improves compression resistance, making bottles more durable. Enhanced barrier properties extend product shelf life. Whether processing polypropylene injection stretch blow molding or PET applications, our technology consistently delivers premium quality.

High Precision & Stability

Full process automation with advanced servo control systems ensures exceptional dimensional accuracy and product consistency across high-volume production runs. Computer-controlled parameters eliminate human error and variation in critical process variables.

Precision control of injection pressure, temperature profiles, stretch timing, and blow pressures guarantees uniform wall thickness distribution and consistent bottle geometry. Real-time monitoring and closed-loop control systems continuously optimize production parameters.

High Material Utilization

The integrated single-stage process minimizes material waste throughout production, with only minimal tail trimming required. No preform storage, transportation, or reprocessing steps mean significantly less scrap material and handling waste.

This efficient material usage translates directly to reduced raw material costs and improved profitability. The closed-loop process reduces contamination risks and maintains material purity, eliminating the need for regrind systems common in two-stage operations.

Complete Integration for Maximum Efficiency

Our one-step ISBM technology combines injection molding, conditioning, stretching, and blow molding into a single automated cycle. This integration eliminates multiple process stages, reduces equipment footprint, lowers labor requirements, and ensures superior product quality with outstanding production efficiency.

Energy Reduction

Process Automation

Footprint Reduction

Quality Consistency

Unlock Versatile Packaging Solutions with Ever Power One-Step Injection Stretch Blow Molding (ISBM) Machines

Tailor-Made Production for Your Diverse Needs

Ever Power’s advanced one-step ISBM machines excel in processing an extensive range of materials, such as PE, PP, PS, SAN, EVA, COC, PEEK, TPU, PETG, and PET. Capable of producing bottles from 1 ml to 1000 ml, these machines support a broad spectrum of industries, including pharmaceuticals, cosmetics, household products, and food packaging. This comprehensive adaptability guarantees precise fulfillment of your unique packaging demands, delivering efficiency and superior quality.

Explore the potential of Ever Power’s ISBM technology to optimize your manufacturing processes. Reach out to our experts today for customized consultations and innovative solutions.

Service

One-Step vs. Two-Step ISBM

| Aspect | One-Step ISBM (Ever Power) | Two-Step ISBM |

|---|---|---|

| Forming Method | Single machine integrates injection, stretching & blow molding | Separate machines: injection molding + blow molding |

| Forming Process | • Two stations: Preform → Blow molding (no reheating) • Three stations: Preform → Stretch blow molding (no reheating) • Four stations: Preform → Transfer to heating station → Temperature control → Stretch blow molding | Preform molding and blow molding are completely separate processes with independent heating and temperature control |

| Equipment Configuration | 1. One machine produces multiple bottle types 2. Hot-runner preform method | 1. Injection machine for preforms 2. Preform storage & handling line 3. Reheat stretch blow machine 4. Cold-runner preform method |

| Labor / Energy / Space | Low (minimal operators, lower energy use, compact footprint) | High (more operators, higher energy for reheating, larger factory space needed) |

| Product Quality | • Less contamination & moisture absorption • Wide variety of shapes & sizes • Low defect rate | • Prone to contamination & moisture • Limited shape variety • Higher defect rate |

Working Principle of One-Step Injection Stretch Blow Molding (ISBM) Machines

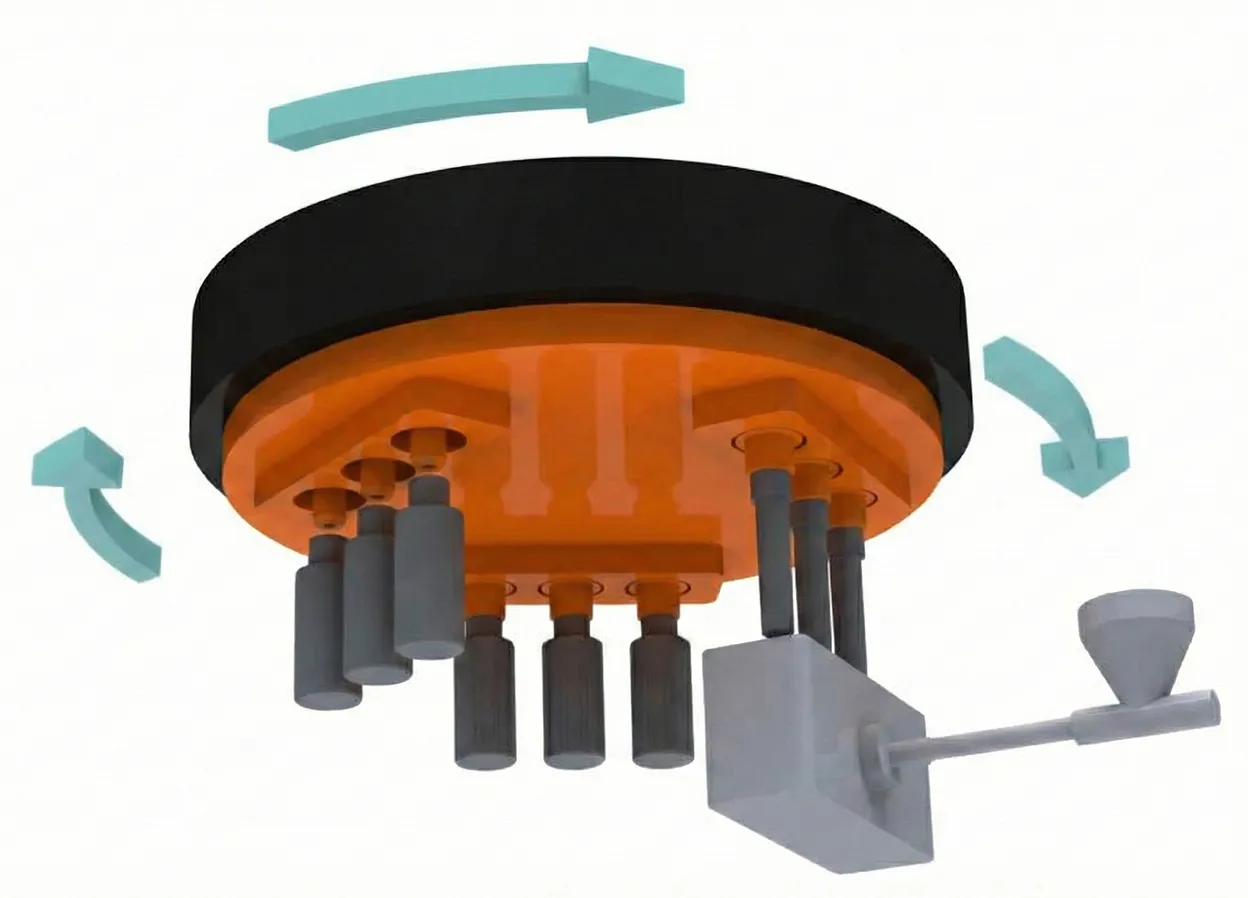

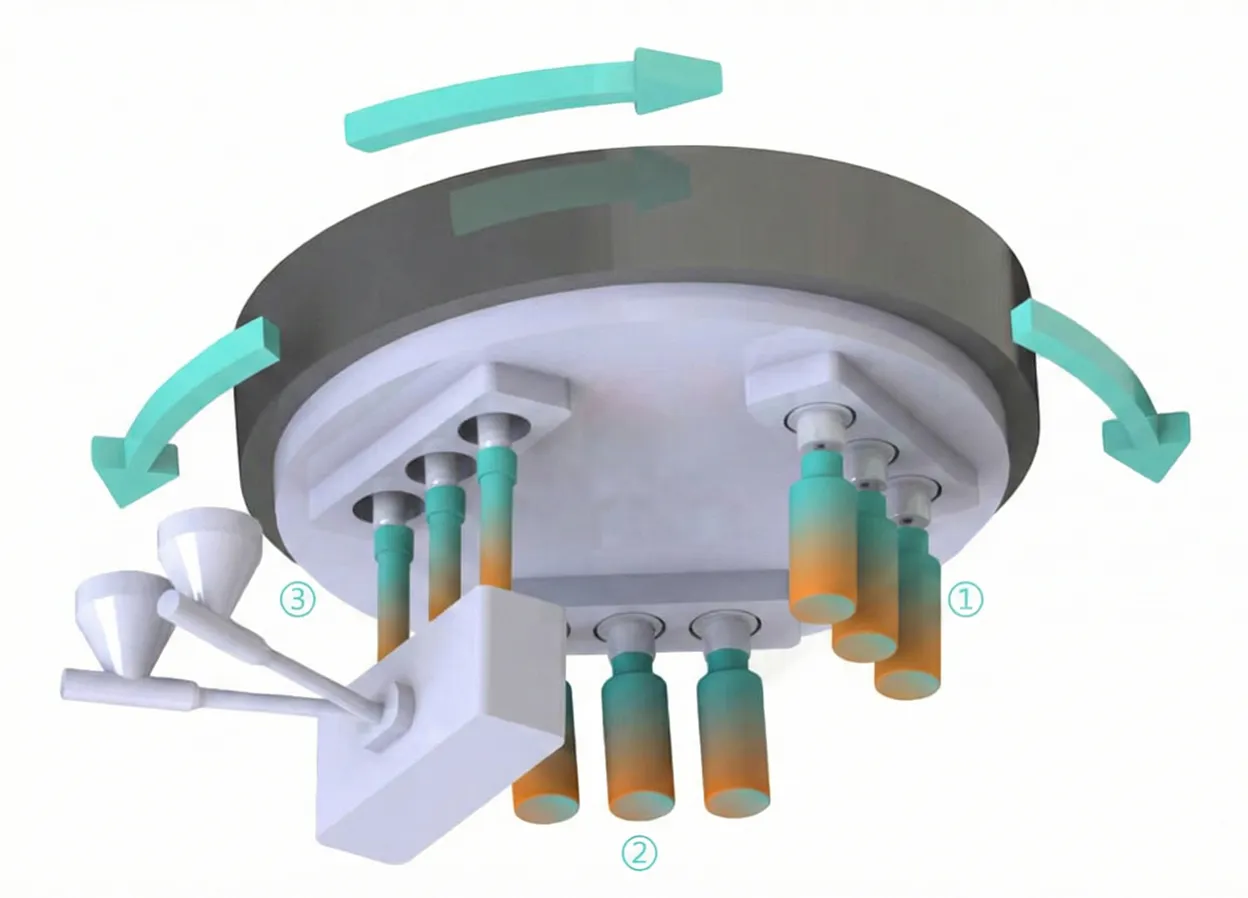

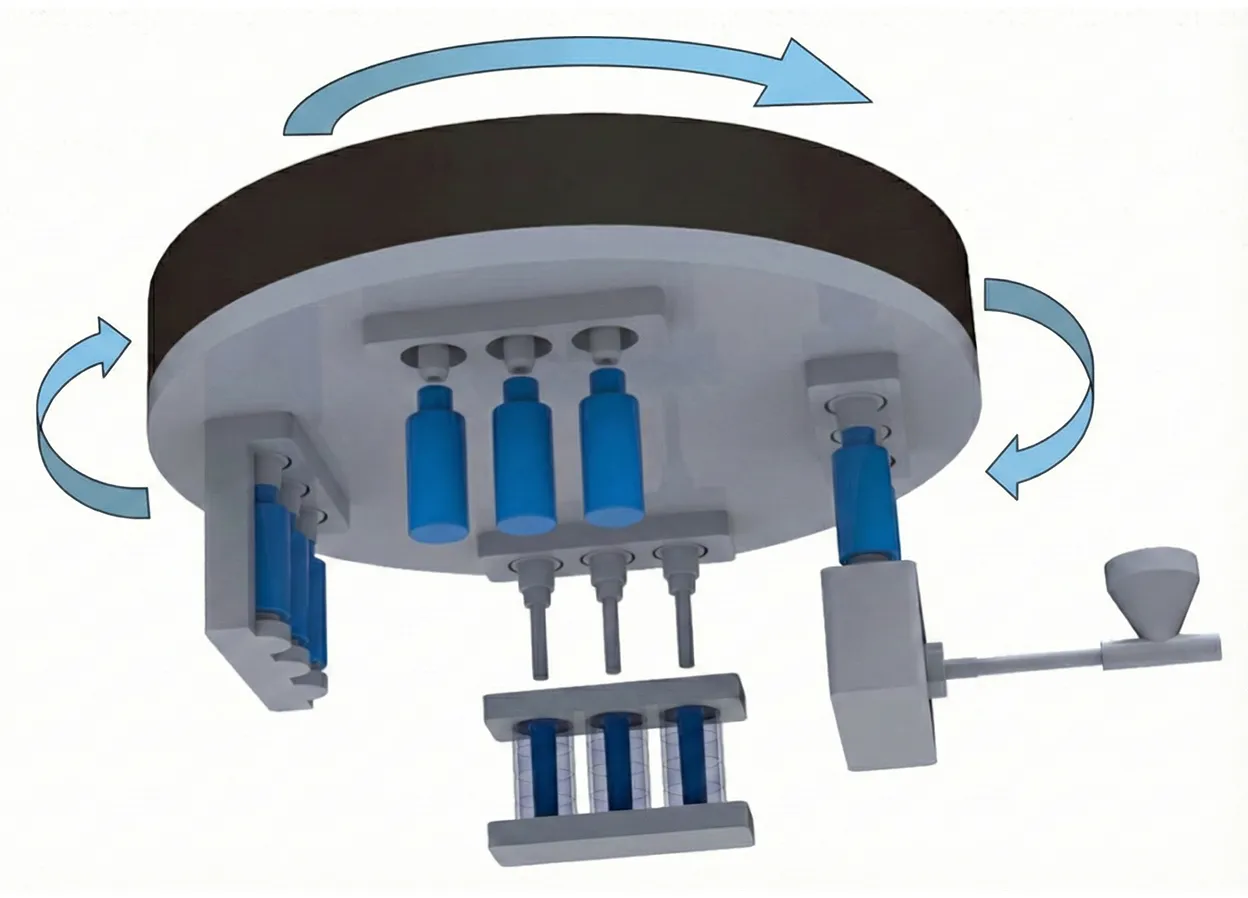

Ever Power ISBM Machine Co., Ltd. employs an integrated design in its one-step injection stretch blow molding machines. This approach consolidates the processes of injection molding, temperature conditioning (via a unique four-station method), stretch and blow molding, and container release within a single unit. Consequently, plastic raw materials are transformed into finished containers efficiently, minimizing deformation and damage from preform transfers across separate equipment. This ensures consistent quality and stability in the final products.

- Injection Molding Station: Plastic raw materials are heated and melted, then injected into the preform mold to create the initial preform shape.

- Temperature Conditioning Station (Unique Four-Station Process): The preform undergoes precise heating or cooling as dictated by process specifications, utilizing a specialized four-station configuration for optimal thermal control.

- Stretch and Blow Molding Station: The preform is extended longitudinally and transversely to improve toughness and transparency, followed by the introduction of high-pressure air to expand it rapidly within the blow mold, forming the completed containers.

- Container Release Station: The finished containers are separated from the mold for collection and further handling.

3 Station ISBM

3 Station ISBM(Two Color)

4 Station ISBM

Application: ISBM Bottles

The One-Step Injection Stretch Blow Molding (ISBM) process developed by USA ISBM Machine Co., Ltd. is utilized for manufacturing high-precision plastic containers. This method integrates injection and blow molding into a single cycle, ensuring consistent wall thickness and neck dimensions.

Cosmetic Bottles

In the cosmetic industry, ISBM technology is selected for its ability to produce PET containers with high optical clarity.

- Technical Characteristics: Minimal surface defects, precise neck finish for pump compatibility, and consistent base stability.

- Common Uses: Serum bottles, lotion containers, and toner packaging.

Cell Culture Flask

Laboratory-grade containers require strict adherence to optical and geometric specifications.

- Technical Characteristics: Flat growth surfaces and high clarity for microscopic analysis; manufactured under controlled conditions.

- Common Uses: T25, T75, and T175 flasks for biotechnological research.

Plastic Dropper Bottle

Pharmaceutical and chemical applications require high dimensional accuracy to ensure proper closure fit and dosage control.

- Technical Characteristics: Precise molding of small-capacity bottles (5ml–50ml) and consistent orifice dimensions.

- Common Uses: Ophthalmic solutions, essential oils, and diagnostic reagents.

Food Bottle

The one-step process produces containers that meet standard food-grade requirements while maintaining structural integrity.

- Technical Characteristics: Controlled wall thickness distribution and suitability for wide-mouth jar configurations.

- Common Uses: Honey jars, sauce containers, and spice bottles.

Water Bottle

For the bottled water sector, ISBM machines provide a balance between lightweight design and vertical load strength.

- Technical Characteristics: High transparency and optimized material distribution to reduce resin consumption per unit.

- Common Uses: Still and sparkling mineral water packaging.

Feeding Bottle

Safety is non-negotiable. Our One-Step process eliminates the risk of secondary pollution, making it ideal for the infant care industry.

- Key Features: Compatible with BPA-Free materials like Tritan™ or high-grade PET; smooth, burr-free necks for nipple attachment.

- Applications: Standard and wide-neck baby bottles, sippy cups.

Plastic Beer Bottle

A specialized application requiring advanced barrier technology to protect the beer from oxygen and UV light.

- Key Features: Multi-layer or additive-enhanced PET for extended shelf life, shatterproof safety for stadiums/events, and 100% recyclability.

- Applications: Craft beer, event-specific beverage packaging.

Beverage Bottle

Handling internal pressure requires a robust molecular structure. Our stretch-blowing process aligns molecules for maximum strength.

Key Features: Superior CO2 barrier properties to maintain carbonation, and high thermal stability for hot-fill applications.

Applications: Juice bottles, energy drinks, and carbonated soft drinks (CSDs).